Productbeschrijving:

De Solenoïdeklep Diafragma is een cruciaal onderdeel dat specifiek is ontworpen voor gebruik met ASCO Solenoïdekleppen en Pneumatische Kleppen. Dit diafragma is ontworpen om betrouwbare en efficiënte prestaties te leveren en is ideaal voor toepassingen die precieze controle van de vloeistof- of gasstroom vereisen onder wisselende drukcondities. Met een drukclassificatie van 0-10 Bar is het geschikt voor een breed scala aan industriële en commerciële toepassingen, waardoor een consistente werking binnen de gespecificeerde druklimieten wordt gegarandeerd.

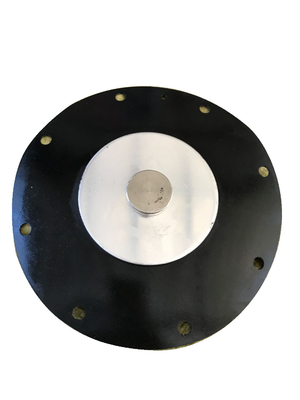

Gemaakt van hoogwaardig nitrilrubber, biedt het diafragma uitstekende duurzaamheid, flexibiliteit en weerstand tegen slijtage. Nitrilrubber staat bekend om zijn uitstekende weerstand tegen oliën, brandstoffen en andere chemicaliën, waardoor het een ideaal materiaal is voor solenoïdeklep diafragma's die vaak in contact komen met verschillende media. Deze materiaalkeuze zorgt voor langdurige prestaties en vermindert de frequentie van onderhoud of vervangingen, waardoor de algehele betrouwbaarheid van het solenoïdeklepsysteem wordt verbeterd.

Dit diafragma is compatibel met ASCO Solenoïdekleppen, specifiek ontworpen om te passen op 2-weg Pneumatische Solenoïdekleppen, die veel worden gebruikt in automatiserings- en vloeistofregelsystemen. De precieze pasvorm garandeert een optimale afdichting en efficiënte werking, waardoor lekkages worden voorkomen en ervoor wordt gezorgd dat de klep nauwkeurig reageert op regelsignalen. Of het nu wordt gebruikt in pneumatische systemen of andere vloeistofregeltoepassingen, dit diafragma draagt bij aan de soepele werking van de klep.

De opties voor de bedrijfsspanning voor dit solenoïdeklep diafragma zijn 12V, 24V, 110V en 220V, afhankelijk van het specifieke solenoïdeklepmodel waarmee het wordt gecombineerd. Deze veelzijdigheid in spanningscompatibiliteit maakt integratie in verschillende elektrische opstellingen mogelijk, waarbij rekening wordt gehouden met verschillende operationele vereisten en regionale energienormen. Het diafragma ondersteunt de betrouwbare werking van de solenoïdeklep over deze spanningsbereiken, waardoor consistente prestaties en responsiviteit worden gegarandeerd.

Het werkingsprincipe van het solenoïdeklep diafragma is pilot-gestuurd. In een pilot-gestuurde solenoïdeklep fungeert het diafragma als een flexibele barrière die reageert op veranderingen in de pilotdruk die worden geregeld door de solenoïde spoel. Wanneer de solenoïdespoel wordt bekrachtigd, verschuift deze de pilotdruk, waardoor het diafragma beweegt en de klep opent of sluit. Dit mechanisme maakt efficiënte controle van hogedruk vloeistoffen of gassen mogelijk met relatief weinig elektrisch vermogen, waardoor het een energie-efficiënte oplossing is voor industriële automatisering.

Dit solenoïdeklep diafragma is een essentieel onderdeel van hogedruk solenoïdeklepsystemen, waardoor ze veeleisende toepassingen met drukken tot 10 Bar aankunnen. De compatibiliteit met 2-weg Pneumatische Solenoïdekleppen maakt het een veelzijdige keuze voor veel vloeistofregelsituaties, waaronder lucht, water en andere niet-corrosieve vloeistoffen. De robuuste constructie en precieze engineering van het diafragma zorgen ervoor dat de klep een strakke afdichting behoudt en soepel werkt, waardoor uitvaltijd wordt verminderd en de systeem betrouwbaarheid wordt verbeterd.

Samenvattend is de Solenoïdeklep Diafragma gemaakt van nitrilrubber een hoogwaardig vervangingsonderdeel dat is ontworpen om te passen op ASCO Solenoïdekleppen en 2-weg Pneumatische Solenoïdekleppen. Geclassificeerd voor drukken tot 10 Bar en compatibel met meerdere bedrijfsspanningen (12V, 24V, 110V, 220V), ondersteunt het het pilot-gestuurde werkingsprincipe, wat zorgt voor een efficiënte en betrouwbare klepwerking. Dit diafragma is onmisbaar voor het handhaven van de prestaties van hogedruk solenoïdeklepsystemen, waardoor duurzaamheid, chemische bestendigheid en precieze controle in verschillende industriële toepassingen worden gegarandeerd.

Kenmerken:

-

Productnaam: Solenoïdeklep Diafragma

-

Temperatuurbereik: -20°C tot 80°C

-

Installatietype: Inschroeven

-

Hoge corrosiebestendigheid voor langere duurzaamheid

-

Drukbereik: 0 tot 10 Bar

-

Spoeltype: Solenoïde

-

Compatibel met toepassingen voor luchtvering solenoïdekleppen

-

Geschikt voor hogedruk solenoïdeklepsystemen

-

Ideaal voor gebruik in koffiemachine solenoïdeklep opstellingen

Technische parameters:

|

Opening grootte

|

3/4 Inch

|

|

Dikte

|

1,5 mm

|

|

Pasvorm

|

ASCO Solenoïdeklep Pneumatische Klep

|

|

Afdichting

|

Goede afdichting

|

|

Diafragma materiaal

|

Nitrilrubber

|

|

Materiaal

|

NBR (Nitrilbutadieenrubber)

|

|

Temperatuurbereik

|

-20°C tot 80°C

|

|

Spoeltype

|

Solenoïde

|

|

Werkingsprincipe

|

Pilot-gestuurd

|

|

Druk

|

0-10 Bar

|

Toepassingen:

De HONGUM Solenoïdeklep Diafragma, met een opening van 3/4 inch en gemaakt van duurzaam nitrilrubber, is ontworpen om te voldoen aan de veeleisende behoeften van verschillende industriële en commerciële toepassingen. Het inschroefinstallatietype zorgt voor een eenvoudige en veilige montage, waardoor het een ideale keuze is voor systemen die een betrouwbare en efficiënte klepwerking vereisen. De uitstekende afdichtingsmogelijkheden van het diafragma garanderen minimale lekkage, waardoor de algehele prestaties en levensduur van het klepsysteem worden verbeterd.

Dit product is met name geschikt voor gebruik met luchtvering solenoïdekleppen, waarbij precieze controle van de luchtstroom en -druk cruciaal is voor het handhaven van de stabiliteit en het comfort van het voertuig. Het nitrilrubber diafragma biedt weerstand tegen slijtage, waardoor een consistente werking wordt gegarandeerd, zelfs bij frequent schakelen en blootstelling aan wisselende omgevingsomstandigheden. De goede afdichtingseigenschappen helpen de integriteit van het luchtveringssysteem te behouden, waardoor luchtverlies wordt voorkomen en een soepele rijkwaliteit wordt gegarandeerd.

Bovendien is het HONGUM diafragma compatibel met hogedruk solenoïdekleppen, die vaak worden gebruikt in hydraulische en pneumatische regelsystemen. De robuuste constructie van het diafragma maakt het bestand tegen hogedruk omgevingen, waardoor het een uitstekende component is voor het regelen van de vloeistofstroom in veeleisende toepassingen. De mogelijkheid om een strakke afdichting te behouden onder druk draagt bij aan de veiligheid en efficiëntie van hogedruksystemen, waardoor het risico op lekkages en systeemfouten wordt verminderd.

Bovendien werkt het diafragma naadloos samen met hydraulische solenoïdeklep spoelen, wat zorgt voor betrouwbare activering en controle in hydraulische circuits. Het solenoïdespoeltype dat in dit diafragma is geïntegreerd, zorgt voor een snelle en precieze klepwerking, wat essentieel is in toepassingen zoals industriële machines, autosystemen en vloeistofregelsystemen. De combinatie van nitrilrubber materiaal en solenoïdespoeltechnologie verbetert de responsiviteit en duurzaamheid van het diafragma, waardoor het een betrouwbare component is in hydraulische klepassemblages.

Over het algemeen is de HONGUM Solenoïdeklep Diafragma een essentieel onderdeel voor verschillende gelegenheden en scenario's waar betrouwbare klepafdichting en -werking van het grootste belang zijn. Of het nu in luchtveringssystemen, hogedruk omgevingen of hydraulische klepassemblages is, dit diafragma levert uitzonderlijke prestaties, duurzaamheid en installatiegemak, waardoor het een voorkeurskeuze is voor ingenieurs en technici in meerdere industrieën.

Ondersteuning en diensten:

Ons Solenoïdeklep Diafragma product wordt ondersteund door een toegewijd technisch team dat zich inzet voor het garanderen van optimale prestaties en betrouwbaarheid. We bieden uitgebreide installatiebegeleiding, hulp bij het oplossen van problemen en onderhoudstips om de levensduur en efficiëntie van uw solenoïdeklep diafragma te maximaliseren.

Technische ondersteuning omvat gedetailleerde productdocumentatie, compatibiliteitsinformatie en real-time assistentie van ervaren ingenieurs om eventuele operationele problemen op te lossen. We bieden ook reparatie- en vervangingsdiensten om uitvaltijd te minimaliseren en de systeemintegriteit te behouden.

Voor de beste resultaten raden we regelmatige inspectie en reiniging van het diafragma aan om slijtage te voorkomen. Ons ondersteuningsteam kan aangepaste onderhoudsschema's leveren op basis van uw specifieke toepassing en bedrijfsomstandigheden.

Daarnaast bieden we trainingssessies en technische workshops om uw personeel te helpen de juiste hanterings- en installatieprocedures te begrijpen, zodat veiligheids- en prestatienormen consistent worden nageleefd.

Onze toewijding is om responsieve, deskundige ondersteuning en hoogwaardige diensten te bieden die ervoor zorgen dat uw solenoïdeklep diafragma efficiënt werkt gedurende de gehele levensduur.

Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!  Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!